Truss Plate Crack Detection Plan

Release date:

Jul 07,2025

Information Summary:

1. Transportation and Stacking:

1) Truss composite panels shall be transported to the site using vehicles equipped with dedicated protective measures. The stacking area for truss composite panels must be leveled and hardened, and each panel must be supported by underlays.

2. Visual inspection and sampling quantity for truss composite panels:

1) Inspect the geometric dimensions of the truss composite panels to ensure there are no chipped corners or cracks, and that all parameters meet the criteria specified in the appearance quality table. Proceed to the next inspection step.

2) The sampling inspection quantity for truss composite panels shall be 1% of the total number of panels, with each sampled group containing no fewer than 3 panels. If the first sampled group meets the visual quality requirements, the sampling rate for the same batch will remain at 1%. However, if the first sampled group fails to meet the visual quality requirements, the number of re-inspection groups shall be increased to 2, with 3 panels per group. If the re-inspection results still fail to meet the visual quality requirements, the entire batch of composite panels shall be deemed nonconforming, strictly prohibited from use, and a record of withdrawal from the site must be kept. (Undamaged specimens may be used in the project.)

3. Truss Composite Slab Loading Test:

(1) According to the unsupported span specifications and models of truss composite slabs, erect a loading support frame on-site. Place the truss slabs onto the support frame. The test load shall be the total load applied during the construction phase, and the loading shall be carried out in three uniform increments:

1) After the first loading is complete, pour water onto the top surface of the truss deck. After 10 minutes, check whether there are any water stains on the bottom surface of the deck.

2) After the second loading is completed, pour water onto the top surface of the truss deck and observe the bottom surface of the deck for any signs of water leakage after 10 minutes.

3) After the third loading is completed, pour water onto the top surface of the truss deck and observe whether there are any water stains on the bottom surface of the deck 10 minutes later.

(2) Acceptance criteria: The test results must meet the parameter requirements specified in the appearance quality table to be considered合格 (qualified).

4. Test loading tools and materials:

One set of adjustable leveling truss composite slab test support frame.

Load with usage code or bricks weighing 2000 kg.

Bucket, ladle, tap water.

5. Based on the standard:

1) Based on the national standard “Cement-based Non-removable Bottom-formwork Steel Truss Floor Deck for Rural Houses” (under review)

2) According to Appendix E of the industry standard “Technical Specification for Application of Non-Dismantlable Bottom-Formwork Steel Truss Composite Slabs” (under review): Water-spraying test.

3) Based on the group standard T/CECS 1069-2022, "Technical Code for Application of Steel Bar Truss Composite Slabs"

Appearance quality

Serial number |

Project |

Indicator |

1 |

Hole |

Should not have |

2 |

Crack |

The length of any single crack shall not exceed 50 mm, the crack width shall not exceed 0.1 mm, and there shall be no more than 2 cracks per board. |

3 |

Chipped edges and corners |

No more than 20 mm in length and no more than 10 mm in width, with a maximum of 2 defects per board. |

The test load should adopt the standard combination of loads applicable during the construction phase.

It can be calculated using the following formula:

In the formula: F —— test load;

F s — Standard value of the self-weight of steel-bar truss floor slabs;

F c — Standard value of the self-weight of post-poured concrete and additional reinforcement;

F q — The standard value of live load during the construction phase can be taken as 1.5 kN/m. 2.

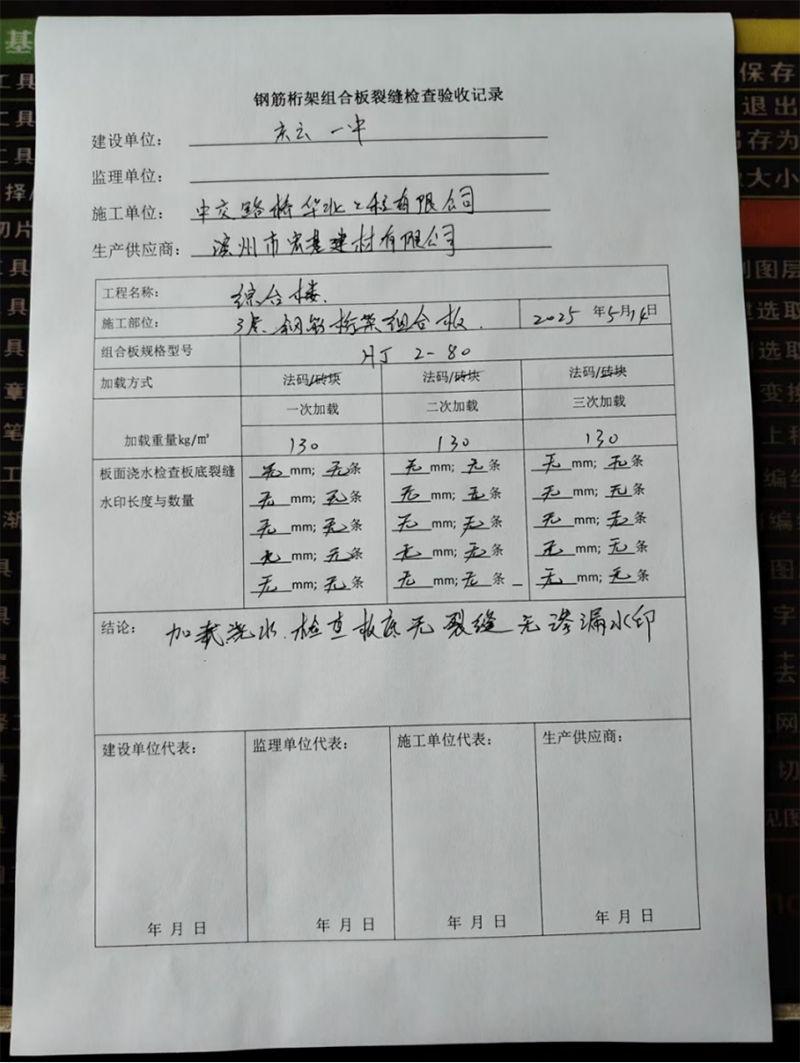

Reinforced Steel Truss Composite Slab Crack Inspection and Acceptance Record

Construction Unit:

Supervision Unit:

Construction unit:

Production supplier:

| Project Name: | |||

| Construction location: | Year Month Day | ||

Composite board specifications and models |

|

||

Loading method |

Brick/block |

Brick/block |

Brick/block |

Loading weight kg/m² |

One-time loading |

Second loading |

Three-time loading |

|

|

|

|

Check the surface for water stains and measure the length and number of cracks on the underside of the board. |

mm; item |

mm; item |

mm; item |

Conclusion: |

|||

Representative of the construction unit:

Year Month Day |

Representative of the supervision unit:

Year Month Day |

Representative of the construction unit:

Year Month Day |

Production supplier:

Year Month Day |

1) Place the truss deck on the support frame.

A board is randomly selected from the stockpile.

On-site erection of loading support frame

The truss deck is placed on the support frame.

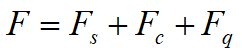

2) After the first loading is complete, pour water onto the top surface of the truss deck. After 10 minutes, check whether there are any water stains on the bottom surface of the deck.

First-time loading of weights: 130 kg/㎡

After 10 minutes, observe that there are no water leakage marks on the bottom surface of the board.

3) After the second loading is completed, pour water onto the top surface of the truss deck. After 10 minutes, observe whether there are any water seepage marks on the bottom surface of the deck.

Second-stage loading weight: 130 kg/㎡

After 10 minutes, observe that there are no water leakage marks on the bottom surface of the board.

4) After the third loading is completed, pour water onto the top surface of the truss deck. After 10 minutes, check whether there are any water seepage marks on the bottom surface of the deck.

Three times loading weights of 130 kg/㎡

After 10 minutes, observe that there are no water leakage marks on the bottom surface of the board.

Binzhou Hongji Building Materials Co., Ltd.

June 15, 2025

More information

Truss Plate Crack Detection Plan

2025-07-07