Jinan's

Category: Company News

Published Time: 2019-12-17

Summary: Jinan's

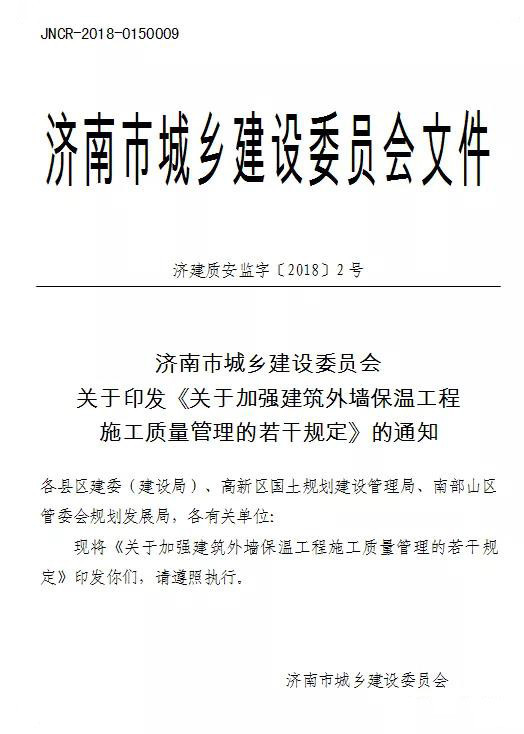

Notice of the Jinan Municipal Committee of Urban and Rural Construction on Issuing the "Several Provisions on Strengthening the Quality Management of Construction of Exterior Wall Insulation Engineering"

To the Construction Committees (Construction Bureaus) of all counties and districts, the High-tech Zone Land and Resources Planning and Construction Management Bureau, the Nanbu Mountain Area Management Committee Planning and Development Bureau, and all relevant units:

The "Several Provisions on Strengthening the Quality Management of Construction of Exterior Wall Insulation Engineering" are hereby issued to you for your compliance.

Jinan Municipal Committee of Urban and Rural Construction

August 1, 2018

Several Provisions on Strengthening the Quality Management of Construction of Exterior Wall Insulation Engineering

Chapter 1 General Provisions

Article 1 In order to strengthen the quality management of the construction of exterior wall insulation engineering and effectively prevent quality hidden dangers such as falling off and leakage of exterior wall insulation engineering, this regulation is formulated in accordance with relevant laws, regulations and technical standards, combined with the actual situation of our city.

Article 2 Anyone engaged in the construction of new building exterior wall insulation projects and related supervision and management activities within the administrative area of this city shall abide by these provisions.

Article 3 These provisions mainly apply to exterior wall insulation systems that paste insulation boards on the outer side of the building exterior wall and then apply a thin plaster, including expanded polystyrene board thin plaster exterior wall insulation systems, rock wool board thin plaster exterior wall insulation systems, etc.

For exterior wall insulation systems that integrate insulation with the building exterior wall structure, non-transparent curtain wall exterior wall insulation systems, and insulation decorative board exterior wall insulation systems, the relevant management requirements and technical requirements should be implemented in accordance with these provisions.

Article 4 The use of exterior wall insulation systems that integrate insulation with the building exterior wall structure is encouraged.

Article 5 The main bodies responsible for the quality of construction, construction, and supervision of engineering projects are legally responsible for the construction quality of exterior wall insulation projects. The exterior wall insulation system supplier is responsible for the quality of the system and materials provided, and the quality inspection institution is responsible for the inspection reports issued.

In addition to strictly implementing these provisions, the above-mentioned responsible entities and units should also implement the relevant provisions on building energy efficiency supervision.

Chapter 2 Basic Provisions

Article 6 The construction unit must include the exterior wall insulation project in the overall construction management and bear the primary responsibility for the quality of the exterior wall insulation project; the construction unit shall not subcontract the exterior wall insulation project; the general contractor shall strengthen the education and training of the operational skills of the construction personnel for the exterior wall insulation project.

Article 7 The design depth of the construction drawings for exterior wall insulation projects shall comply with relevant national regulations. Specific methods and relevant technical measures must be clearly defined for key parts and key nodes involving safety and important use functions.

The construction unit shall not arbitrarily change the construction drawings of the exterior wall insulation project that have been reviewed and approved. If changes are necessary, the design change documents shall be processed according to the prescribed procedures; changes involving safety and... shall be approved by the original review and approval institution.

Article 8 The exterior wall insulation system must have a valid "Shandong Province New Wall Material Building Energy Efficiency Technology Product Certification Certificate" (hereinafter referred to as the "Certification Certificate") and a type test report.

The structure of the exterior wall insulation system and the types of various constituent materials must be consistent with the content of the certification certificate and the type test report; the constituent materials of the system must be provided by the system supplier.

Article 9 During the construction of the exterior wall insulation project and within 24 hours after completion, the base layer and ambient air temperature should not be lower than 5℃. Avoid sun exposure in summer. Construction shall not be carried out in strong winds above level 5 and in rainy or snowy weather.

Article 10 For new technologies and new materials used in exterior wall insulation projects that do not have national or local standards, the construction unit shall organize relevant experts to conduct special demonstrations on their applicability, key points of technical quality control, and acceptance requirements.

Chapter 3 Construction Preparation

Article 11 Before the construction of the exterior wall insulation project, the construction unit shall organize the design, supervision, general contractor (professional subcontractor), and system supplier to conduct a special review of the construction drawings and form a review record. For key parts and key nodes involving safety and important use functions, if the specific methods and relevant technical measures are unclear, supplementary detailed design documents shall be provided.

Article 12 After the completion of the special review, the general contractor (professional subcontractor) shall prepare a special construction plan based on the construction drawings, review records, relevant technical standards, material product instructions, and expert opinions, and submit it to the supervision unit for review and approval.

If the special construction plan has obvious traces of copying, empty content, lack of pertinence and operability, the supervision unit shall not approve it.

Article 13 When the constituent materials of the exterior wall insulation system enter the site, the general contractor shall report to the supervision unit in a timely manner after self-inspection and qualification. The supervision unit shall conduct on-site acceptance according to the following requirements:

1. Based on the certification certificate and type test report, confirm whether the constituent materials of the system are provided by the system supplier, and whether the system structure and material types are consistent with the content of the certification certificate and type test report.

2. Verify whether the quality certification documents of the constituent materials of the system are complete and valid, and inspect and accept their appearance quality.

3. For materials such as insulation boards, adhesives and surface coatings, and alkali-resistant fiberglass nets that need to be re-inspected upon entering the site, the samples taken must be randomly selected from the materials that have entered the site, and sent for inspection after being jointly witnessed and sealed by relevant personnel from the construction, construction, supervision, and quality inspection institutions.

Materials that have not passed the on-site acceptance or have failed the on-site acceptance are strictly prohibited from being used in the project.

Article 14 Before the large-scale construction of the exterior wall insulation project, the general contractor (professional subcontractor) shall use the same materials and processes to make a sample wall on the project entity. The sample wall shall meet the following requirements:

1. It should be made on a project (bid section) basis. If multiple exterior wall insulation systems are used in the same project (bid section), they should be made separately.

2. It should be set at the corner of the gable wall and the outer longitudinal wall, with an area of no less than 20㎡, and should include at least one exterior window opening and one exterior wall projecting component.

3. A sign should be set up to display the types of materials in each structural layer of the exterior wall insulation system layer by layer.

4. A sign should be set up to show the method of pasting insulation boards and the requirements for bonding area, the method of anchor bolt fixing and the requirements for anchoring depth, etc., in the form of pictures and texts.

While creating the sample wall, relevant sample components should be made for testing the bonding strength between the insulation board and the base layer, and the anchoring force of the anchor bolts. A quality inspection agency with the relevant qualifications should be commissioned to conduct on-site pull-out tests.

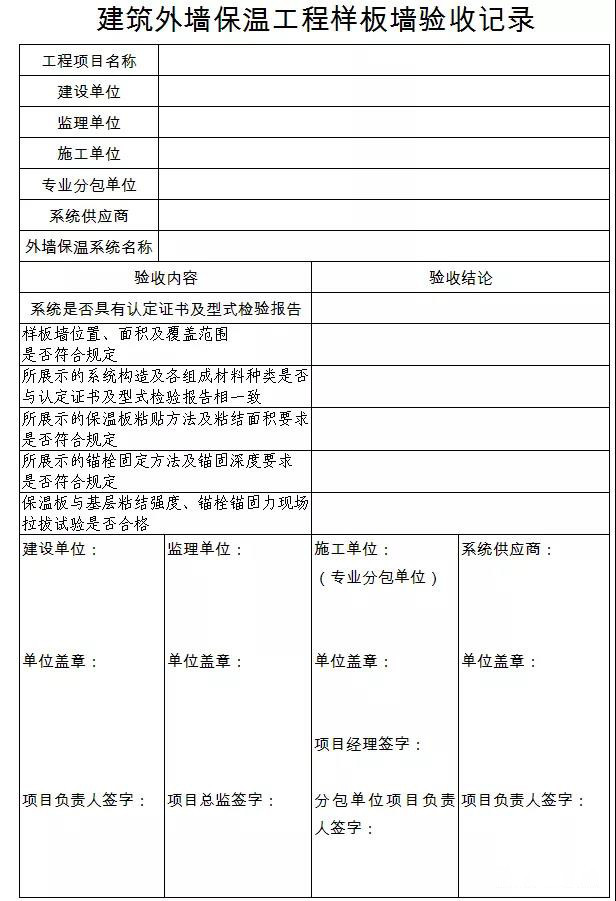

After the sample wall is completed and the on-site pull-out test is qualified, the construction unit should organize the supervisor, general contractor (professional subcontractor), system supplier, and other units to conduct a joint acceptance inspection and generate an acceptance record (acceptance record format see attachment); large-scale construction can only be carried out after the joint acceptance inspection is passed.

Article 15 Before the large-scale construction of the exterior wall insulation project, the project technical person in charge of the general contractor should conduct a technical handover to all construction operators based on the special construction plan and combined with the sample wall object, and form written and video records of the handover.

Chapter 4 Construction, Acceptance and Inspection

Article 16 Before the exterior wall insulation board is pasted, the exterior wall base layer should be treated according to the following requirements:

1. All kinds of construction holes on the exterior wall surface (mainly including through-wall bolt holes, temporary reserved holes for scaffolding cantilever steel and connecting wall components, etc.) should be sealed tightly and waterproof treatment should be carried out on their facing surfaces; waterproof treatment should be carried out on the inner corner parts of various exterior wall protruding components. The types and specific methods of waterproof materials should meet the design requirements, and cement-based penetrating crystalline waterproof coatings are recommended.

2. Polymer mortar should be used to level the base layer wall surface. The leveling layer should be firmly bonded, the surface should be flat and clean, and the surface flatness deviation should not exceed 5mm.

It is strictly forbidden to directly paste the insulation board on the untreated base layer wall to prevent exterior wall leakage or the insulation board from not being firmly attached due to the unevenness of the base layer wall.

Article 17 In addition to strictly implementing relevant current national and local technical standards, the construction of exterior wall insulation board pasting should also meet the following requirements:

1. Interface treatment must be carried out before pasting XPS boards and rock wool boards. For XPS boards, a special interface agent should be sprayed on the two large surfaces. For rock wool boards, a waterproof interface agent should be sprayed on the two large surfaces and four small surfaces.

2. When mixing the adhesive for pasting insulation boards on site, the amount should be strictly measured according to the product instructions, and it should be used within the specified time. Do not add water again.

3. For EPS/XPS boards, the point-frame method or strip bonding method should be used. The bonding area of the gable wall should not be less than 60%, and the bonding area of other parts should not be less than 40%;

For rock wool boards, the full bonding method without cavity should be used for the gable wall, and the strip bonding method can be used for other parts. The bonding area should not be less than 60%.

It is strictly forbidden to use the point bonding method to paste insulation boards to prevent the gaps on the back of the insulation boards from being connected and magnifying the wind load effect; for rock wool boards, metal brackets should also be used for support. The specifications, quantity, and position of the metal brackets should meet the design requirements.

4. The insulation boards at the four corners of the window openings should be cut into shape in one piece and should not be spliced; the two ends of the deformation joints must be filled with insulation boards according to the design requirements.

5. In order to prevent rain and snow water from seeping into the gap between the insulation board and the base layer and causing frost heave, waterproof sealing treatment should be carried out at the system starting and ending parts such as the base, deformation joints, exterior wall openings, and parapet wall tops.

Article 18 In addition to strictly implementing relevant current national and local technical standards, the construction of exterior wall insulation board rendering mortar and anchor bolt installation should also meet the following requirements:

1. When mixing the rendering mortar on site, the amount should be strictly measured according to the product instructions, and it should be used within the specified time. Do not add water again.

For EPS/XPS boards, the rendering mortar layer should be constructed in two times, and a layer of alkali-resistant fiberglass mesh should be pressed into the first rendering mortar. A layer of alkali-resistant fiberglass mesh should be added at the junction of the fire isolation belt and the insulation board during the second rendering mortar construction (the overlapping width should not be less than 200mm).

For rock wool boards, the rendering mortar layer should be constructed in three times, and a layer of alkali-resistant fiberglass mesh should be pressed into the first and second rendering mortar constructions.

Alkali-resistant fiberglass mesh should be used for wrapping at the system starting and ending parts such as the base, deformation joints, exterior wall openings, and parapet wall tops. Corner mesh should be used for reinforcement at the inner and outer corners to prevent cracking of the rendering mortar due to stress concentration and prevent rain and snow water from seeping in.

2. The number of anchor bolts should meet the design and relevant standard requirements; anchor bolts should be set at the four corners and the middle of the horizontal seams of the insulation board. The longitudinal spacing should not be greater than 300mm, the transverse spacing should not be greater than 400mm, arranged in a plum blossom shape, the spacing at the base corner should not be greater than 200mm, and at least 3 anchor bolts should be arranged on each side around the window opening.

The effective anchoring depth of the anchor bolt should meet the design and relevant standard requirements. It should not be less than 35mm in concrete walls and not less than 60mm in masonry walls.

For EPS/XPS boards, the diameter of the plastic disc of the anchor bolt should not be less than 50mm; for rock wool boards, the diameter of the plastic disc of the anchor bolt should not be less than 140mm.

Anchor bolt installation should be carried out after the first rendering mortar (including alkali-resistant fiberglass mesh) construction is completed; anchor bolt drilling and installation should be carried out strictly according to the product instructions. It is strictly forbidden to use hammering to install; when drilling, the drill bit diameter of the drilling tool should be adapted to the diameter of the plastic expansion tube, the hole depth should be 5-10mm greater than the anchoring depth, and the dust in the hole should be cleaned up in time.

Article 19 During the construction of exterior wall insulation board pasting and rendering mortar and anchor bolt installation, the general contractor (professional subcontractor) unit shall strictly carry out self-inspection and process handover inspection in accordance with this regulation and relevant technical standards, and the supervisor shall implement inspection and acceptance of key construction links according to the following requirements:

1. Concealed acceptance inspection should be strictly implemented for each inspection batch, and image materials should be attached. The concealed acceptance content includes: waterproof treatment and overall leveling treatment of the exterior wall base layer, interface treatment of insulation boards, bonding method and bonding area rate of insulation boards, setting of alkali-resistant fiberglass mesh, specifications, position and effective anchoring depth of anchor bolts, etc.

2. After completion of each inspection batch construction, at least 3 representative insulation boards should be randomly exposed and inspected to verify the bonding method, bonding area rate, and effective anchoring depth of anchor bolts, and a written and image inspection record should be generated.

If any one of the inspection items, such as the bonding method of the insulation board, the bonding area rate, and the effective anchoring depth of the anchor bolt, fails to meet the requirements, the inspected area is deemed unqualified.

If 2 or more of the 3 randomly exposed inspection areas are unqualified, the inspection batch is deemed unqualified. If 1 area is unqualified, 6 more areas should be randomly selected for inspection. If 1 or more areas are still unqualified, the inspection batch is deemed unqualified; if all 6 additional areas are qualified, the inspection batch is deemed qualified, and the unqualified areas found in the first inspection should be reworked.

If the inspection is unqualified, relevant supervisory documents should be issued immediately, ordering the general contractor (specialized subcontractor) to rework and re-inspect and accept.

If the general contractor (specialized subcontractor) refuses to rectify, it should be reported to the construction unit and the engineering quality supervision institution in a timely manner.

Article 20 After the completion of the exterior wall insulation rendering layer construction, the construction unit shall entrust a quality inspection institution with the corresponding qualifications to conduct on-site pull-out tests on the bonding strength between the insulation board and the base layer and the anchoring force of the anchor bolts.

1. For the on-site pull-out test of the bonding strength between the insulation board and the base layer, the number of tests for each type of base layer wall in each unit project shall be no less than one group, with no less than 5 test points per group.

2. For the on-site pull-out test of the anchor bolt anchoring force, each 3 layers of exterior walls in each unit project shall be considered as one test batch. When the exterior wall area of the test batch is no more than 1000m2, 3 test points shall be randomly selected. When the exterior wall area of the test batch is more than 1000m2, 1 point shall be added for every increase of 500m2; if the increased area is less than 500m2, it shall be calculated as 500m2. The exterior wall area referred to in this section is the sum of the orthogonal projection areas of all facades of each floor exterior wall, excluding the area of exterior window openings.

When selecting test points within the test batch, at least 1 test point should be selected for each type of base layer wall, and at least 1 test point should be selected for each floor. Test points on adjacent upper and lower floors should be selected on different exterior wall facades.

3. Before the on-site testing, the testing institution shall prepare a testing plan based on the engineering design documents, standards, and testing contracts, and obtain the approval of the technical director of the testing institution and the confirmation of the commissioning party. The testing institution shall inform the supervision institution of the testing plan at least 5 working days in advance.

4. On-site test points should be numbered and a schematic diagram should be generated. Image records should be kept for test point layout and testing process. The supervision unit shall witness the testing according to regulations and promptly sign and confirm the test point layout schematic diagram and the original testing records.

5. The testing plan, test point layout schematic diagram, and testing image records of the testing institution should be archived together with the original testing records and testing report. The testing report issued by the testing institution should indicate the measured values. Unqualified reports should be promptly reported to the supervision institution.

Article 21 For the on-site pull-out test results of the anchor bolt anchoring force of the unit project, all test points must be 100% qualified.

When the qualification rate is 90% or above and the minimum value is no less than 85% of the design value, the design unit can review the safety of the exterior wall insulation system; when the qualification rate does not reach 90% or the minimum value does not reach 85% of the design value, a qualified appraisal and testing institution should be entrusted to appraise the safety of the entire exterior wall insulation system. If reinforcement is required according to the appraisal, the design unit shall provide processing opinions, and after the construction unit completes the rectification, the testing institution shall re-test the anchor bolt anchoring force according to the regulations, and the acceptance can be organized only after the test is qualified.

Chapter 5 Supervision and Management

Article 22 The engineering quality supervision institution shall supervise and inspect the construction quality of exterior wall insulation projects according to the following requirements, taking the engineering project (bid section) as a unit:

1. Inspect the exterior wall insulation sample wall.

2. Supervise and inspect the main components of the exterior wall insulation system.

For residential communities and other large-scale development projects, a set of samples shall be selected for testing according to the same engineering project (bid section), the same insulation system, and the same manufacturer. The supervision and inspection report can replace the on-site witnessed sampling and testing report.

3. Supervise and inspect the anchoring force of exterior wall exterior insulation fasteners and the bonding strength between the insulation board and the base layer.

For residential communities and other large-scale development projects, one unit project shall be tested according to the same engineering project (bid section) and the same exterior wall insulation specialized subcontractor. The specific number of tests shall be implemented in accordance with Article 20 of these regulations. The supervision and inspection report can replace the on-site physical inspection report.

Article 23 For problems found in supervision and inspection that violate these regulations and relevant laws, regulations, and technical standards, the engineering quality supervision institution shall take measures such as ordering rectification within a time limit, suspension of work for rectification, rework, appraisal and testing, credit score deduction, and transfer to the urban management and law enforcement department for administrative punishment, depending on the circumstances.

Chapter 6 Supplementary Provisions

Article 24 During the construction, inspection and acceptance, quality testing, and quality supervision of exterior wall insulation projects, reliable measures must be taken to ensure personal safety.

Article 25 Matters not covered in these regulations shall be implemented in accordance with relevant current national and local laws, regulations, and technical standards.

Article 26 These regulations shall come into force on August 1, 2018, and shall be valid for 5 years.

Attachment: Acceptance Record of Exterior Wall Insulation Engineering Sample Wall

Keywords: Jinan's

Related Information

Company News

-

How to choose the right HJ floor deck product?

Time:2025-07-26

-

Understanding the advantages and application scenarios of HJ composite floor decking

Time:2025-07-16

-

HJ non-removable formwork steel bar truss decking is officially launched.

Time:2021-06-08

-

Construction of the prefabricated steel structure experimental office building of Binzhou Hongji Building Materials Co., Ltd. has commenced.

Time:2020-12-02

-

Binzhou Hongji Building Materials Co., Ltd. participated in the "Housing Expo", and its high-quality products attracted widespread attention.

Time:2020-12-02

-

Binzhou Hongji Building Materials Co., Ltd. is proposed to be identified as a "whitelist" enterprise in 2020

Time:2020-04-19

-

Binzhou Hongji Building Materials Co., Ltd. visited the parents of its employees before the Spring Festival

Time:2020-01-21

-

Good news - Binzhou Hongji Building Materials Co., Ltd. is one of the first batch of high-tech enterprises to be identified in the province in 2019

Time:2020-01-02

-

Hongji Concrete Co., Ltd. of Binzhou City, Shandong Province participated in the 2019 Shandong Provincial Construction Industry Association Concrete Branch Annual Meeting

Time:2020-01-02

-

Jinan's

Time:2019-12-17

-

Good news——The CBMF standard compiled by Binzhou Hongji Building Materials Co., Ltd. has passed the review

Time:2019-11-30

-

The installation of the new HW-120 external formwork equipment by Binzhou Hongji Building Materials Co., Ltd. is nearing completion.

Time:2019-10-26

-

Binzhou Hongji Building Materials Co., Ltd. participated in the 2019 Anhui International Green Building Materials and Decoration Materials Expo

Time:2019-10-26